Off-line Programming

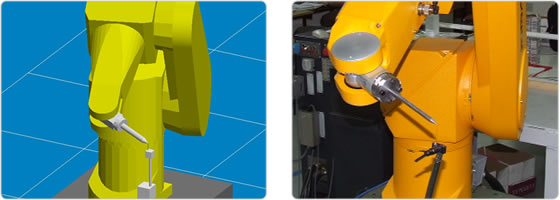

Creating robot programs using interactive computer graphics, whilst the real robot continues in production reduces downtime of robot cells and increases efficiency of manufacturing systems.

Grasp10 is a proven system in industrial use, which creates programs interactively in the simulation model.

Create complex programs in less time using the advanced programming tools, as well as specific application menus for arc welding, palletising and spraying. Import component data as a CAD file if required. Validate and optimise programs off-line using the features of Grasp10 for reach evaluation, joint constraints and cycle time calculation. Download programs directly to the robot in the required robot language.

Robots and Languages Supported.

Models of most industrial robots are available in the robot library while others are available on request. Support is available for most common robot languages and robot controllers. Contact us for further information on the availability of the specific robot and robot language required.Calibration.

An important factor in off-line programming is the inherent inaccuracies of most robots (not to be confused with their repeatability). Grasp10 counters this with in-depth mathematical tools to calibrate the robot and 3D model to match the real world. Unlike other off-line programming tools the Grasp10 calibration procedure requires no special equipment to be hired and set up. It requires only the teaching of a number of robot poses which are then read into Grasp10 and analysed by the calibration software.

Home

Home

Robotics & Automation

Robotics & Automation

About Grasp 10

About Grasp 10

Off-line Programming

Off-line Programming